Ozone Steril Cleaning – an innovation in viticulture

The simply use of OZONE in vine manufacturing.

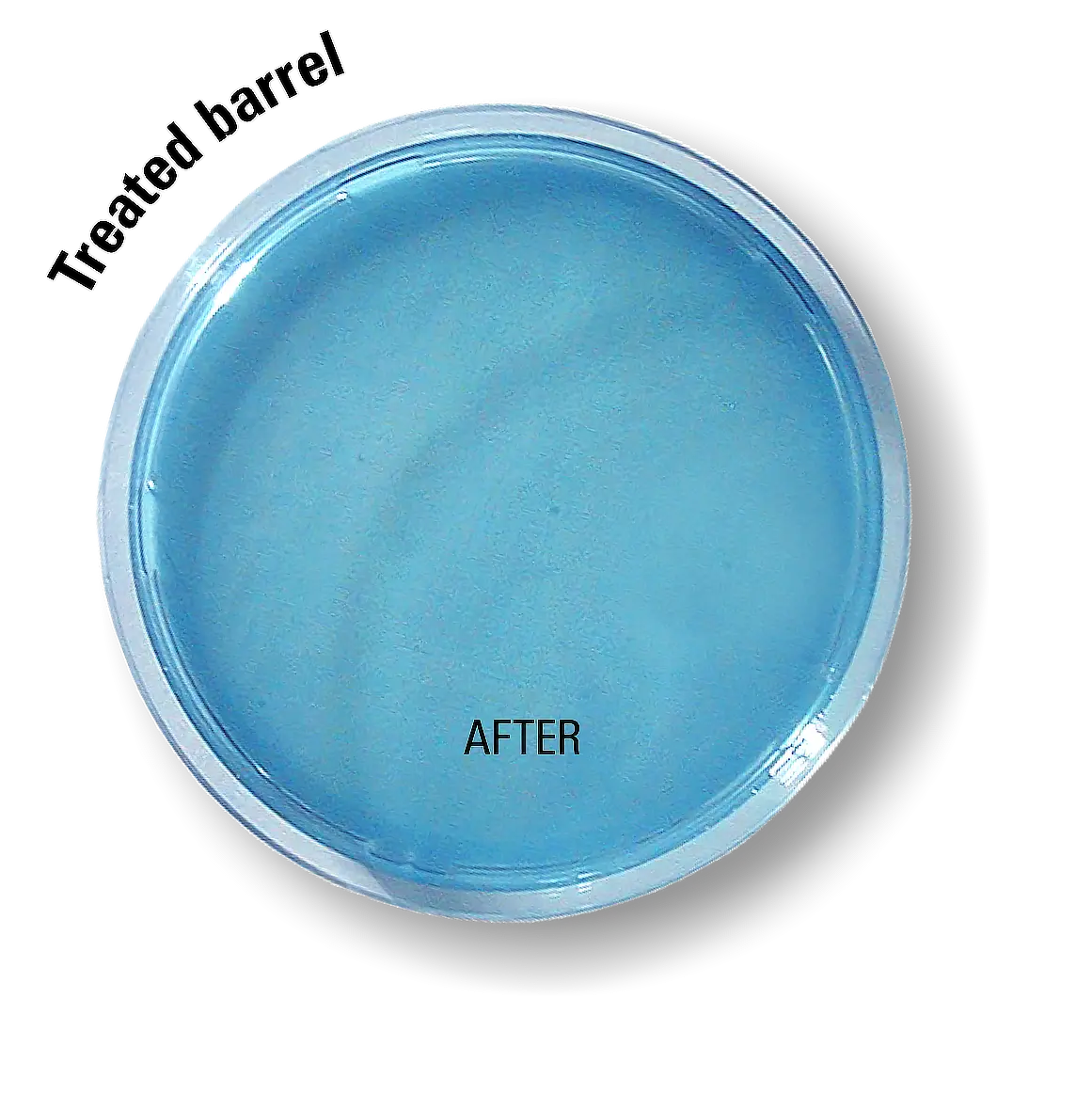

The use of ozone for the cleaning process eliminates reliably germs and bacteria in the barrel. Mould formation and tartar of wine must be avoided.

Why OZONE?

In today’s practice of winemaking, it usually takes weeks or months from cleaning and disinfection to refilling. The empty barrel is stored in the damp cellar until the next use. In case of dry storage, the leak tightness of the barrel is at risk. There is enough time for recontamination so the barrel must be washed and disinfected again before the subsequent refilling.The only economical and sustainable alternative is the treatment with ozone.

OZONE as a solution

Ozone is produced in gaseous form or directly in water. Gaseous ozone can be dissolved in water. This creates ozone water for the sterilisation of bottles,

jugs, metal tanks, pipes, hoses and wooden barrels (Barrique).

OZONE gas

Cleaning and sterilizing barrels and containers is a major challenge for every cooper. Ozone gas destroys germs and bacteria, such as yeasts, and kills them completely.

OZONE water

Ozone dissolved in water has a enormous oxidation power compared to other disinfectants.

Our Product solutionS for the Vinery

OENOCAT® 2.0: The ozone barrel sterilizer as an oxidation agent.

OENOCAT® products use ozone in order to sterilise and preserve containers. Most of the wine lovers prefer the traditional wine, which is aged in oak barrels. Therefore the barrel must be completely cleaned and sterilized before it is filled. Get more information about the 2nd generation of our OENOCAT-FK-36.

How to clean barrels and tanks effectively?

Even afterwards wooden barrels, but also tanks made of metal, need a thorough cleansing to maintain the unmistakable taste of wine.

Our device OENOCAT produces negative ions within the barrel by means of ozone. These ions have a germicidal effect and help to conserve the barrel. The gas enters also the pores in the wood and the gaps between the staves. Odour-creating substances will be oxidised. When using the device, the barrel is sealed and safe because of the plug. According to the low-voltage directive our Oenocat is working with 12 volt DC voltage.

A practical example of the DLR Rhein-Pfalz

The German “Dienstleistungzentrum Ländlicher Raum Rhein-Pfalz“ has tested the effect of the Oenocat in a practical application: Ozone treatment of fermentation tanks is effective and helps to ensure the biological stability within the tanks.

The device can also be used for the treatment of room air in storage rooms and cellars to avoid mould formation.

Anti-bacterial: Ozonated water for rinsing.

Compared to other water disinfectants, ozone is a more than

more than 50% stronger oxidising agent that acts more than

3,000 times faster.

OENOCAT Systems for viticulture processing

Further ozone application in viticulure.

OENOCAT® products use ozone in order to sterilise and preserve containers. Ozone is produced in gaseous form or directly in water. Gaseous ozone can be dissolved in water.

This creates ozone water for the sterilisation of bottles,jugs, metal tanks, pipes, hoses and wooden barrels. It is the environmental alternative to the harmful sulphur cleaning.

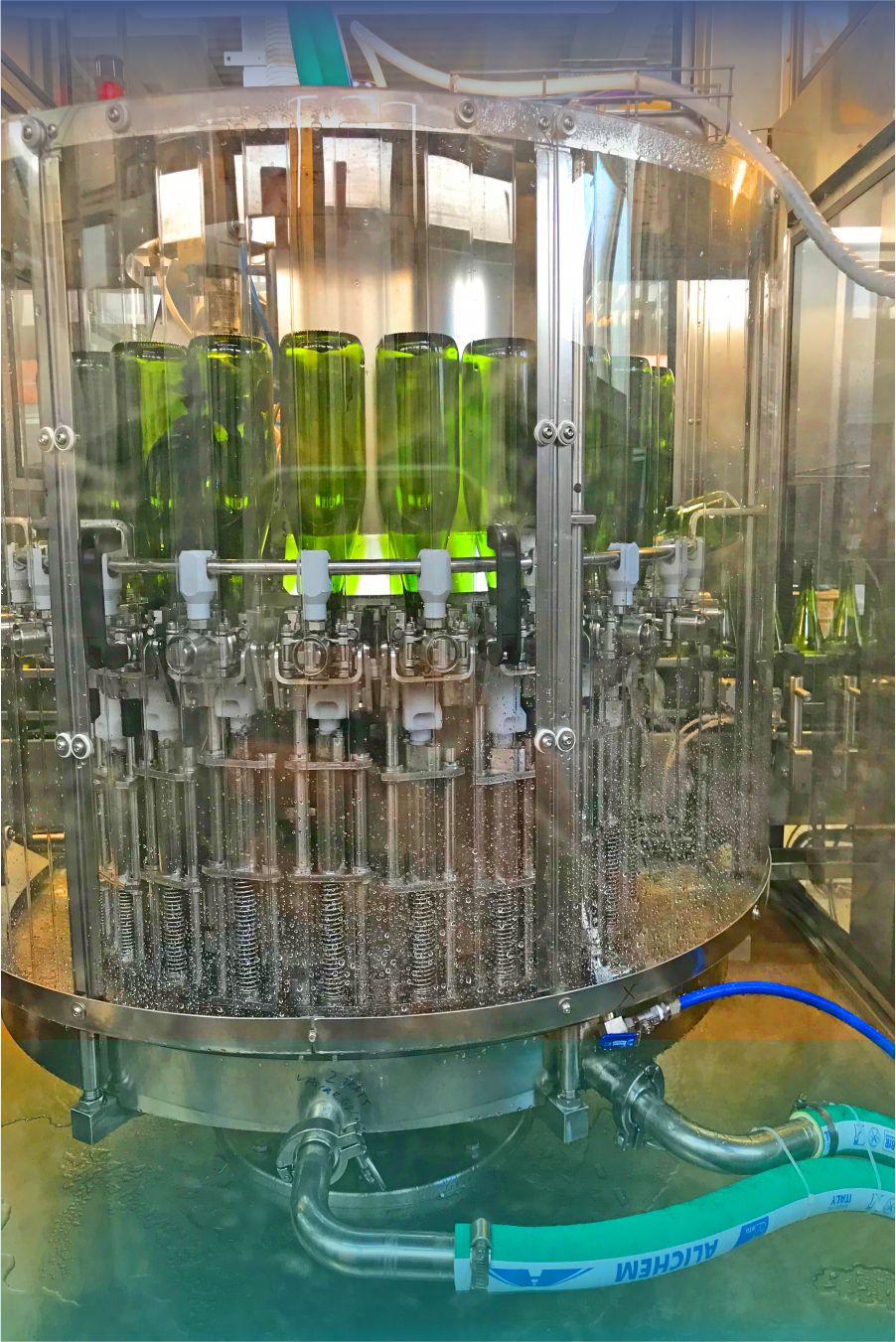

Bottle rinsing

Ozone bottling systems for sterilisation during the rinsing process and removing used detergents.

Cellar hygiene

Hygiene in the cellar or storage guarantees a high wine quality and a further reduction of the application of sulfur.

Fruit storaging

Wines and fruit juices should only be filled into sterilized boxes to minimize the risk of deterioration during storaging.

Our OENOCAT® News blog

OENOCAT® sets a standard for organically grown top wines, which were produced exclusively with Oenocat systems and are free of sulfites.

Take part of Winzer-Service-Messe 2025 !

Visit us from February 5 to 7, 2025 in Hall 11 at Stand D/19.

Germany’s largest trade fair for viticulture, winery management, fruit growing and distilling as well as marketing and sales.

-

UncategorizedExhibition

ANSEROS and OENOCAT meets Weingut & Weinhaus L.Bastian

More than just hot air. Preserving kegs and rinsing bottles before filling with ozone technology from ANSEROS. A super sustainable alternative!

🍷 Many thanks to Mr Andreas Neymeyr from Weingut & Weinhaus L.Bastian in the Kaiserstuhl!

We hope you enjoy using the automatic ANSEROS PAP-B ozone water system for rinsing wine bottles and for gaseous and wet wine barrel treatment. 😉

This solution represents an important step towards sustainable wine production by reducing the amount of sulphur used. Ozone technology is an ecologically sound alternative for barrel preservation and bottle rinsing.

-

UncategorizedEXHIBITION

ANSEROS and OENOCAT will exhibit at ACHEMA 2024 from 10th to 14th June, Frankfurt, Germany

Please visit us at ACHEMA 2024, Frankfurt, Germany, Hall No. 9.0, Booth D66

ACHEMA is the world forum of the process industry and the trend-setting technology summit for chemical engineering, environmental protection and biotechnology. The 32nd ACHEMA exhibition will again be the leading international meeting point for decision-makers and experts from all related industries.

ACHEMA 2023

Date: 10 – 14 June 2023

Stand: Hall No. 9.0, Stand D66

Place: Frankfurt am Main, Germany

Website: www.achema.de

Feedback

Our references

“Physikalische und chemische Alternativen zur Fasskonservierung mittels schwefeliger Säure”, Jahresbericht, Forschungsring des Deutschen Weinbaus bei der DLG e.V., Kompetenzzentrum Weinforschung Dienstleistungszentrum Ländlicher Raum Rheinland-Pfalz, Arbeitskreis Kellerwirtschaft und Weinbehandlung, E. Kritzinger, 2013

Der Luftsterilisator OENOCAT-30; Eine Alternative bei der Holzfasskonservierung? , Sommer, S., Das Deutsche Weinmagazin 19(20), S. 34-36, 2012

“Mehr als heiße Luft – Alternativen zur Fasskonservierung mit schwefeliger Säure”, Das deutsche Weinmagazin, S.22-S.24, 2015

“Renaissance: das traditionelle Eichenfass”, Der deutsche Weinbau, Briegel K., S. 28-31, 2013

“Holzfass Ozon: Einsatz von Ozon zur Behandlung/Stabilisierung von leeren Barriques (Eichenholzfässerm)”, Projektabschlussbericht, DaFNE, 2017“

“DLR Rheinland-Pfalz Aktuell 2013”, Bericht, Veröffentlichungen, S. Sommer, 2013

“Holzfass-Konservierung: Alternative Verfahren, Prinzip des Oenocat-30”, 2024, Vitipendium.de

“Die Preisträger 2013 – Sonderpreis: OENOCAT Fass Sterillisator, ANSEROS Klaus Nonnenmacher GmbH, Tübingen, Deutschland”, ifw-expo.de , 2013

“Innovationspreis: nach strenger Auswahl 29 Neuerungen anerkannt”, www.meininger-verlag.de, ddw, 2013

“Oenocat System για πλήρη καθαρισμό βαρελιών”, weinmagazin, www.oinologia.gr, 2018

“Conservation à sec”, www.wein.plus, 2022

Our story

Hello OENOCAT community!

As an industrial engineer with many years of experience in production technology, Timon Nonnenmacher planned to revolutionise wine production in a natural way. Together with his family business for ozone technology, he developed an ozone generator for the sterilisation of wooden barrels.

The challenge was to develop a powerful generator with a small footprint for barrel cleaning.

The DLR Rheinlandpfalz has tested the OENOCAT and recommends the treatment application for reducing the amountof sulphurous acid used in the preservation of wooden barrels. We have been featured in many renowned magazines for more than 10 years. So we are looking to a green future!

In 2013, together with Klaus Nonnenmacher we won the intervitis interfructa innovation award and presented our product to Minister of State Günther Öttinger.

CONTACT

Get in touch with us..

We are excellently positioned to achieve all your inquiries and questions, across all ozone applications.

Distribution

Official partners